THE DESIGN:

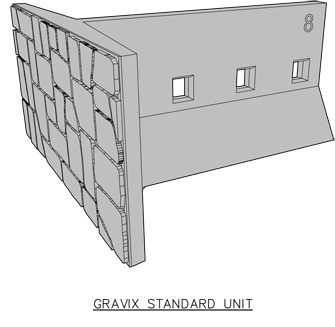

The Gravix® wall units vary in stem depth dependent upon the wall height, as well as surcharge. A standard unit is 32 SF of face area (8’ x 4’). A typical wall section has the longest units at the bottom and get shorter as they are stacked vertically. Also, at the top of a wall, to follow grade, the casting mold is placed on a tilt table to allow the top of the unit to be cast on a slope. The sloping top edge of the units allows all of the unique geometry top units to be precast and customized for each project. The angled precasting also produces a leveling unit to be used directly below traffic barrier units to allow the uniform traffic barrier unit to parallel roadway grade. The precaster can then provide a complete retaining wall package to the highway contractor. Gravix, providing the larger precast unit and a complete retaining wall system, allows the highway contractor to use less labor, common equipment and achieve higher installation rates, saving time and money.

All of the units incorporate a triangular section in the stem perpendicular to the face that allows the weight of the backfill to bear on the units below, thus transferring downward pressure, which results in a stabilizing effect. In combination, the units create a coherent gravity mass designed to resist overturning, sliding and bearing failure. The design methodology follows the well-accepted AASHTO guidelines of a conventional Precast Concrete Bin Wall.